VARI-JET for knit-goods with variable tube diameters

- Tube is opened over the full circumference by so-called singeing basket –shoe

- singeing is effected by 2 linear and 2 semi-circular Double – Jet burners

- When flame meets onto the fabric it is protected by the singeing basket at the tube inside

- Singeing position similar to singeing » onto water cooled roller «

VARI-JET

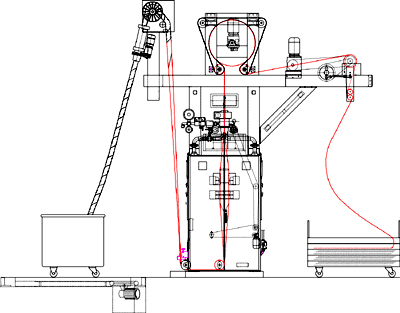

De-twisting device with turn-table, singer VARI-JET, SUPER-VAC contact exhaust, fire quenching device, plaiter / folder

Finishing in tubular form is still the most common process for knit-goods. The tube gets untwisted and is presented fully opened by the singeing basket to the singeing burners. Fabric passes through the contact dust exhaust device before it is guided through the fire quenching unit to the plaiter / folder.